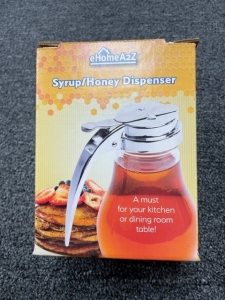

When a brand or business requires packaging or displays with multiple colors or extremely detailed graphics, the best manufacturing method is the use of lithographic labels (litho for short). The process of litho labeled packaging involves:

- Production of labels at a lithographer

- The application of a label coating or special finish

- Mounting/adhering of the labels to the corrugated

- Diecutting into the final flat package design.

Photo Quality Graphics

Producing litho labels is the job of a lithographer such as Packaging Design’s partner, Philipp Lithographing Company (www.philipplitho.com). Litho labels are printed on paper stock using a four color, offset printing process. Four color refers to the fact that almost all colors can be created by a mix of four basic colors, cyan, magenta, yellow, and black (often referred to as CMYK.) Offset printing process means that creating labels is not a process where an image is transferred directly to paper stock. Instead the image is transferred from engraved aluminum press plates (one for each color CMYK), to a cylinder and from there to sheets of paper going through the press.

Litho labels can achieve many different looks through the use of special coatings. Aqueous, and spot UV coatings are applied inline with the printing process at the lithographer. Aqueous coatings are applied to increase the scuff resistance of the label and come in glossy, satin, and matte finishes. UV is a shinier finish which is used in specific spots such as on a logo to make it pop. Another group of label coatings or finishes is film lamination which is a special process completed at a company such as Chicago Laminating Inc. (www.chicagolam.com). Film lamination is a process which uses high heat and pressure to adhere a very durable film to litho labels. In addition to being a durable finish, film lamination reduces or eliminates label cracking which is often seen in dark colored labels upon folding. Film lamination also comes in gloss or soft touch matte finishes as well as numerous specialty finishes such as embossed linen or fine leather patterns.

Film Lamination Coating

Mounting/adhering litho labels to corrugated is done in house at Packaging Design. The labels arrive from Philipp Litho and are run through a machine which applies adhesive to the label and adheres it to a sheet of corrugated board. Afterwards the labeled corrugated sheets are allowed to dry before being diecut on either a flat bed or rotary die cutter (see the November 2021 blog post “How Your Packaging is Made: Corrugated Cutting Dies,” for more information on the process of diecutting).

Here at Packaging Design we are well versed on the use of litho labels on corrugated and are happy to help you navigate the process in order to make your packaging vision a reality. Visit our website, www.pack-design.com, for photo galleries of our work and case studies of successful customer partnerships.