Back in November (that seems like a decade ago now, doesn’t it?) we introduced you to the concept of how your packaging printing projects are estimated and planned. We covered the materials in the first segment, and to refresh your memory, or if you missed it, you can catch it here.

Just after New Year’s, for part two in our series, we explained how packaging construction affects the overall cost and outcome of your project for die-cut items. You can see that article here.

Finally, we have the exciting stuff – THE PRINTING! (Just kidding – it’s ALL exciting!)

Flexographic printing is the most common print process for boxes. The cost of these print plates is part of your tooling which is made for your exact artwork and is a one-time expense. Flexographic plates generally last through many printings, and a manufacturer will often replace them as the quality degrades over time, at no additional cost. Keep in mind though that if you change your artwork you will need new print plates.

Graphic detail

Designs with intricate print details may require machines with more precise print capabilities that are only available at a handful of factories. The manufacturer should be able to work with you and your team to ensure that the graphics you want can be reproduced at the press.

Ink base

Water and oil-based inks are standard, although most manufacturers have gone to water based ink to protect the environment. There are alternative ink bases such as soy and algae but those are more expensive and not in common use.

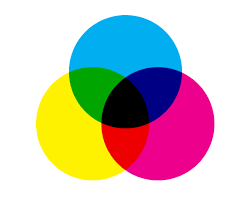

Ink color

Factories will already have CMYK (cyan, magenta, yellow, and black) ink on hand, pre-mixed. Pantone colors (PMS) on the other hand, must be custom mixed, so they are more expensive. If you’re printing CMYK, some colors (especially oranges and purples) may be hard to recreate precisely and will require a custom PMS ink for an exact match.

Number of colors

Each color has its own print plate, so the more colors you have in your design, the higher your tooling cost will be. The number of colors is also directly correlated to the amount of ink required and the amount of setup time and labor involved.

Your education has always been important to us here at Packaging Design. We know that the more informed you are, the better decisions you can make. We are honored that you took the time to read this series, and we would be just as honored to be able to help you by discussing any problems, challenges, or projects you have on the horizon.